Overview of the subject area sound sensor

Sound sensors

Application and distribution partner

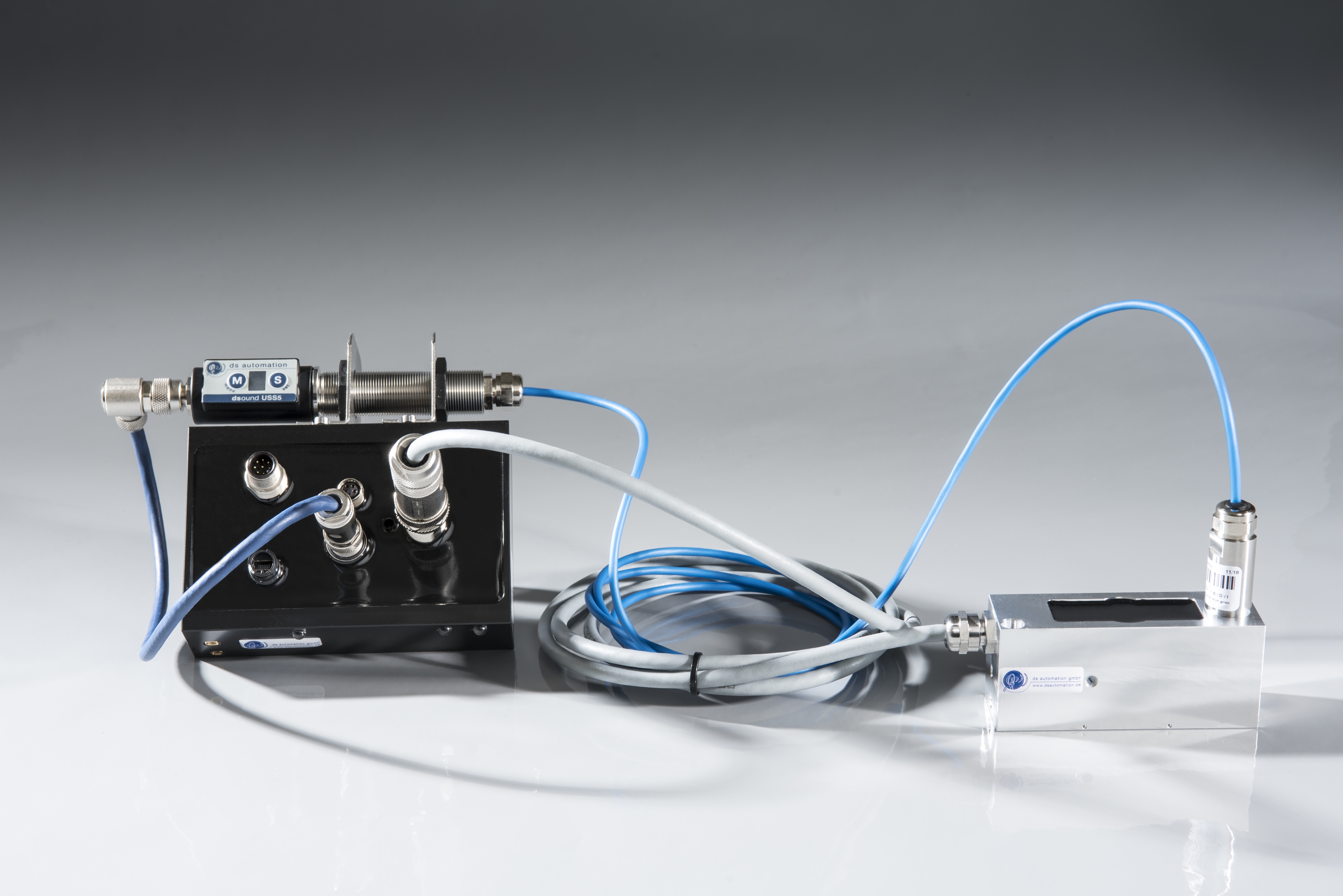

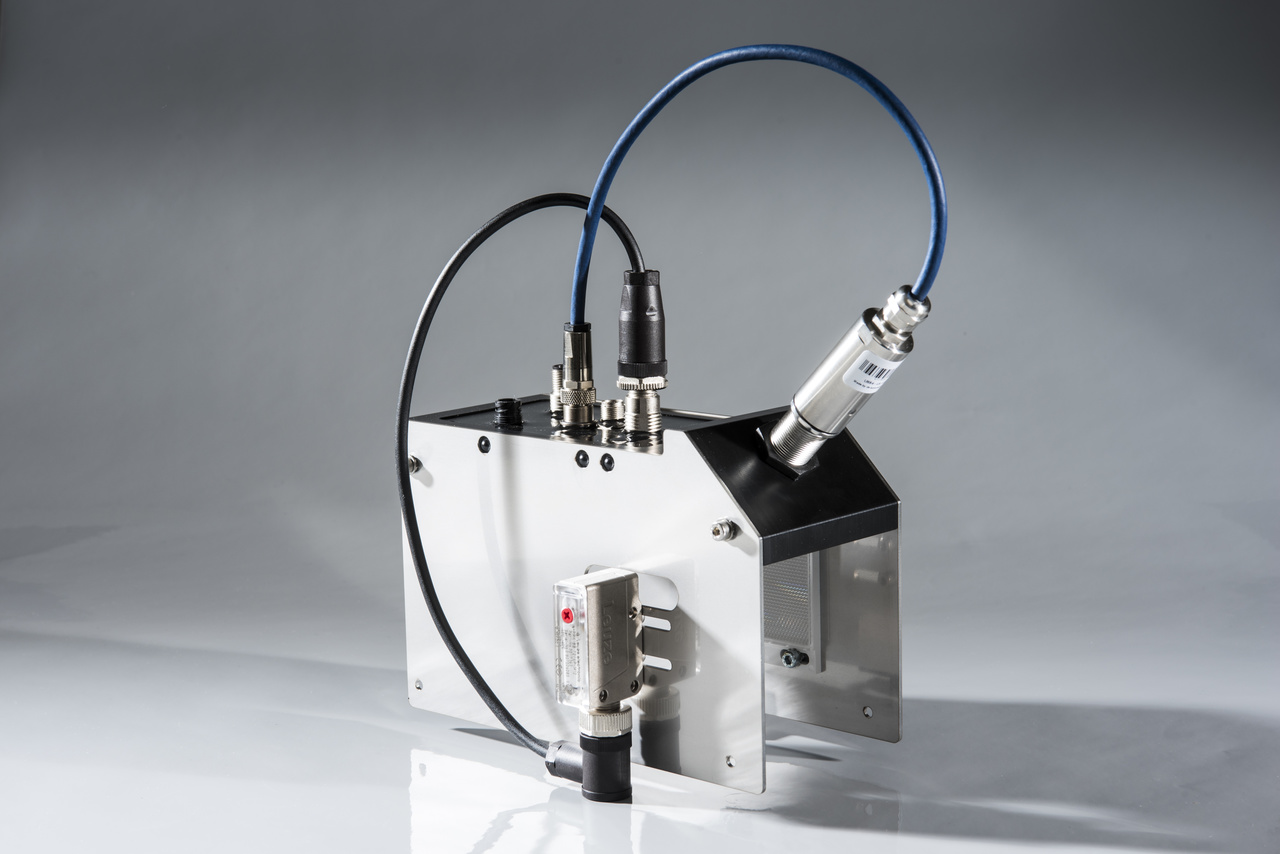

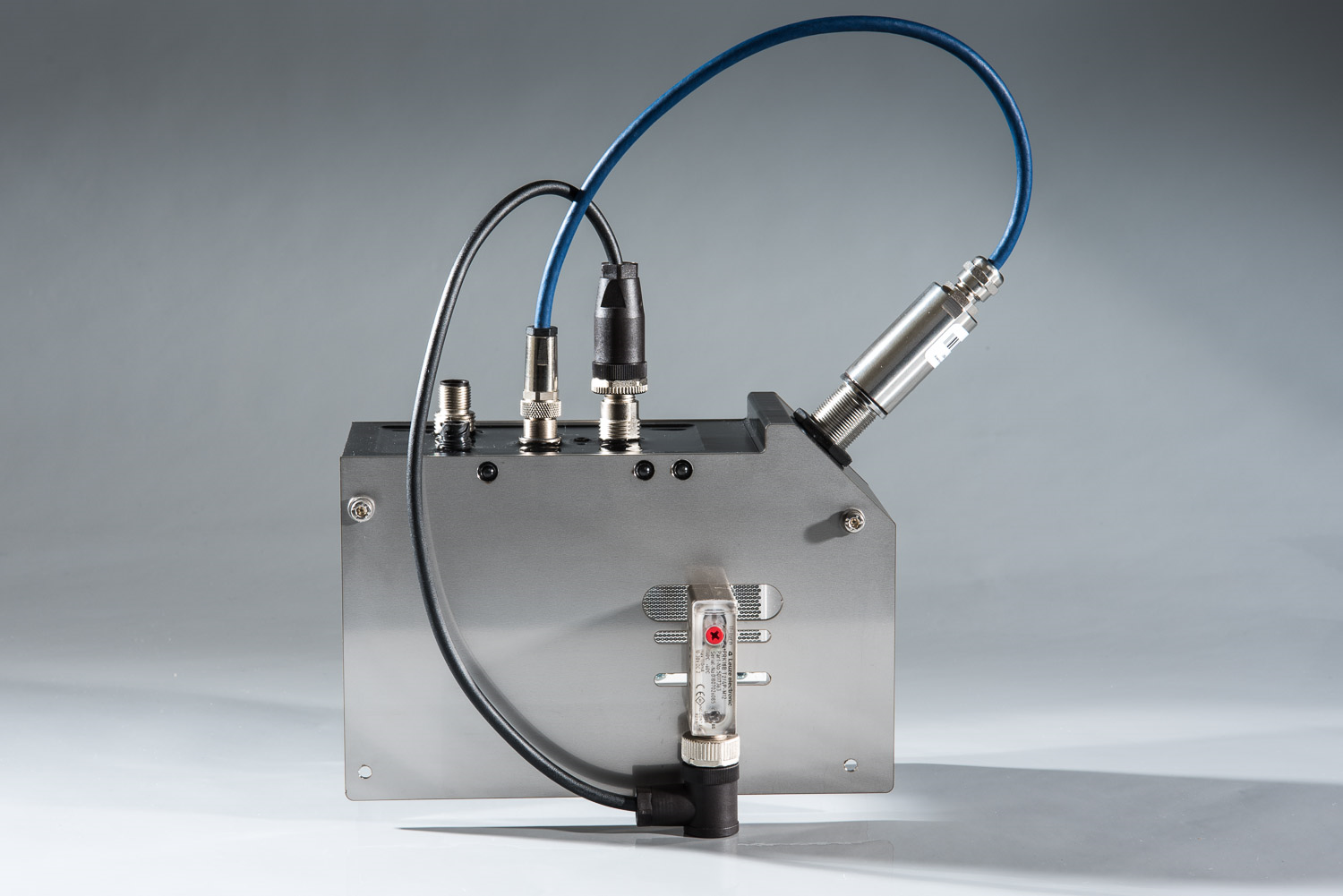

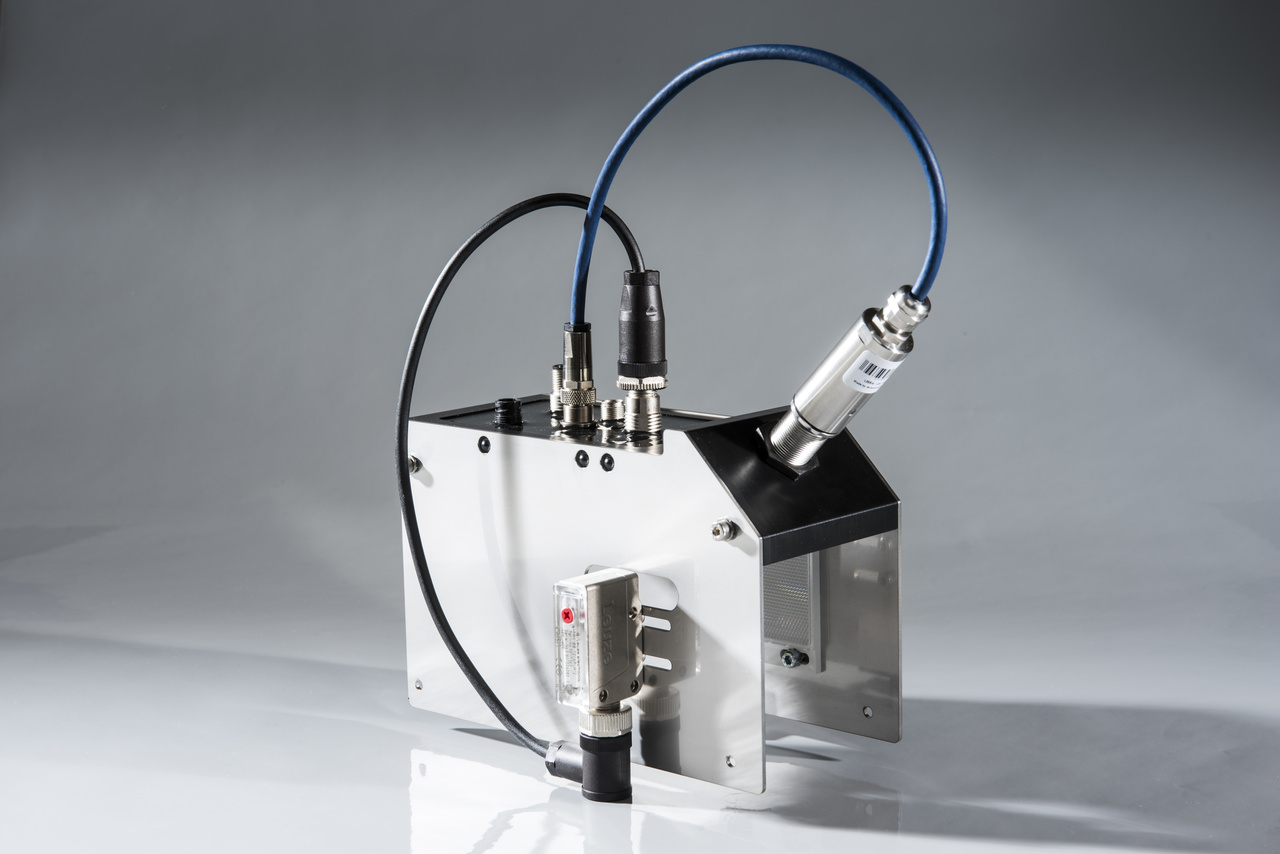

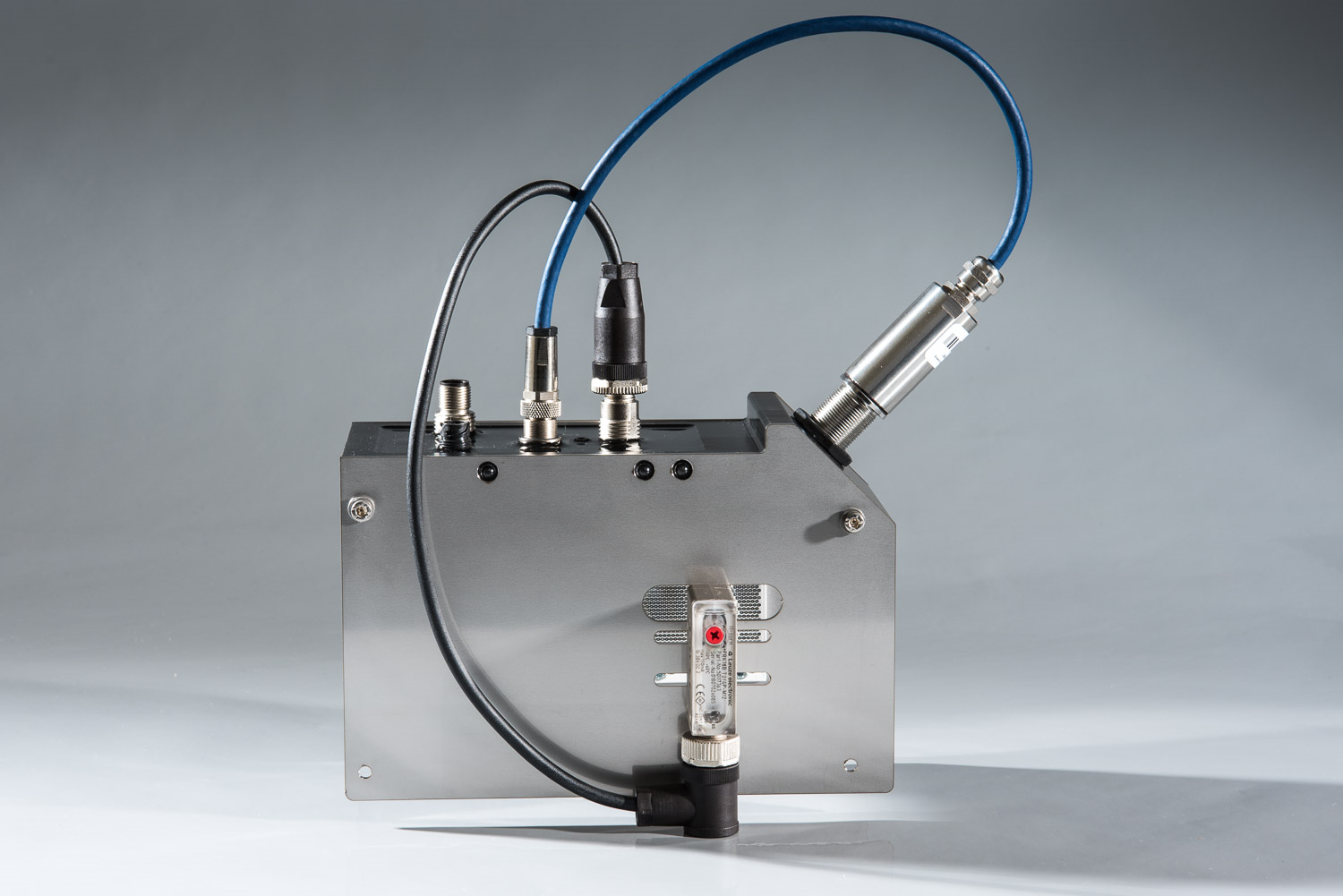

The exciter unit dsound® USE01i enables the quality testing of various objects using acoustic resonance analysis with magnetic excitation in an industrial environment. It is a highly integrated exciter unit that can perform inline object testing using our sound sensors dsound® USS4 and dsound® USS5. This significantly expands the range of applications for our sound sensors.

The exciter unit dsound® USE01k enables the quality testing of various objects using acoustic resonance analysis with mechanical excitation in an industrial environment. It is a highly integrated exciter unit that can perform inline object testing using our sound sensors dsound® USS4 and dsound® USS5. This significantly expands the range of applications for our sound sensors.

The exciter unit dsound® USE01e enables the quality testing of various objects using acoustic resonance analysis with mechanical excitation in an industrial environment. It is a highly integrated exciter unit that can perform inline object testing using our sound sensors dsound® USS4 and dsound® USS5. The dsound® USE01k exciter unit also enables the generation of an exciter pulse for system verification and is used in the dsound® AMS1000 auger monitoring system, among others.